Receive the inspection request from customers(carry it out on site, or at our company by receiving the item, both cases are acceptable)

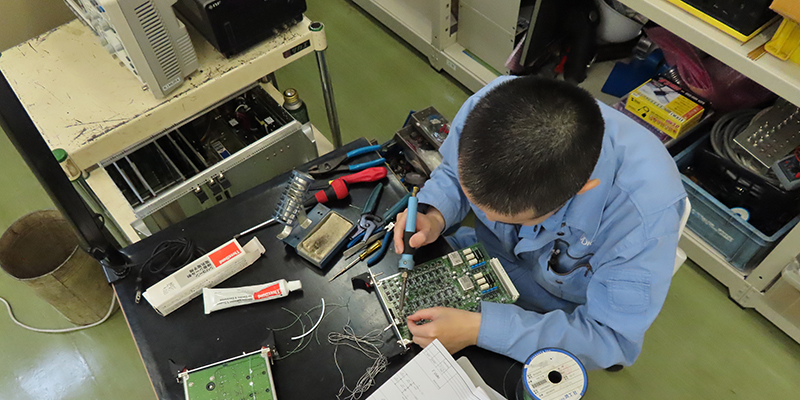

At the inspection, mainly confirming the function of the machine, cleaning, replacing the expendable parts which needs to be exchanged, then finally confirm performance.

Also we will advise expendable items which might need to be replaced in future.

Receive the maintenance request in order to keep the stability of machine performance.

Specify expendable item or parts that might be cause of the problem at further work, carry out the replacement after explaining and getting agreement from customer.

At the same time, it is possible to provide a proposal about the measure for prolong the service life of machine, by confirming the exhaustion state and fatigue condition.

Technical instruction about outline of work will be provided, if inspection and maintenance work are needed within customers.

Information such as key points of inspection, and the timing of when the consultation will be needed, will be provided.

Purchasing an extra expendable items, and spare items are recommended for just in case.

Making a suggestion of recommended spare parts, for quick restoration and identifying cause of problem.

Various types of items are available, such as circuit board, cable, rotational mechanism part, yoke unit, probe, flaw detection coil.

We respond to the consultation which comes up after starting using machine.

If there is any concern or thing needs to be confirmed, please do not hesitate to contact us anytime.

Even if the machine is not made by our company, we respond to a consultation.

※Frequency of the inspection is depend on the type of machine, but once per 1 year to 2 years is recommended.

As for the detail, please ask your sales person in charge, or through our contact window.