This system is used to detect the flaws on the surface of black steel round bar,

especially low straightness or large diameter material.

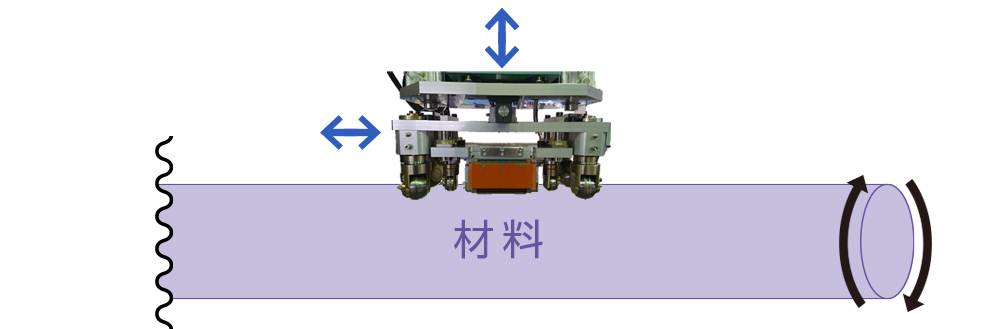

There is two scanning method, one is the material will be rotated,

forwarded and tested by fixed probe called skew forwarding,

another is the probe moves in axial direction on surface of rotating materials at fixed point.

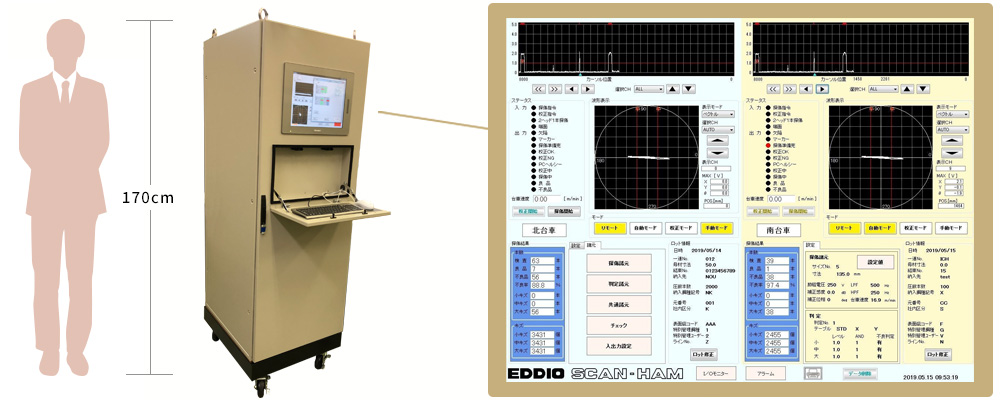

Build up the most appropriate system in full-order-made to use our knowledges and techniques by conducting an interview from the beginning. We can manage wide range about the matter of this system, not only sensor part, but also machine part. Therefore, please feel free to ask us anything.

| Features | ||

|---|---|---|

| Saving detection parameter | Recordable and replayable detection waveform | Excellent simplicity and operability of interface |

| Phase gate evaluation | Built in self-diagnostic system | Touch panel is available |

| Size(mm) |

|---|

| W 600 x H 1710 x D 1010 |

In case of using it for sorting defected material from material supply ※Material fixed and rolling type.

Yoke

This parts are assembled by a hand in our company. We succeed to improve the probe tracking and excitation power efficiency by reducing size and weight. Designed to be stable and durable according to our long manufacturing experience.

Probe

Our probe are winded, and carefully and finely adjusted by a hand in company. Since both of designing and manufacturing of probe are done by our company, we can make custom-made probes applicable to detect various types of materials and flaws according to your request. Therefor, please feel free to contact us.